Happy production

CORA happywear was born in Bolzano from an idea of a group of friends who wanted to create something good and courageous. CORA stands for courage and courage for CORA means to engage in constantly improving production processes in textile industry, constantly choosing raw materials which respect the environment and the skin, follow the rhythms of nature (also human) and be socially sensitive in making business. For us, research and experimenting new ways of consuming fashion are key factors for innovative eco-friendly production.

We work with natural raw materials like beechwood fibre, eucalyptus fibre, bamboo and many other new materials. We do not use chemical treatments or harmful colours and our production sites are certified GOTS, FairWear and Ökotex. We produce in Italy, Greece, and Turkey, having a close eye on the production as we visit our production sites at least once a year. Our objective is to produce cradle to cradle products with the highest standards of eco-sustainability.

From fiber estraction to the natural fabric

CORA happywear fabrics are friends of nature!How are the organic fabrics of CORA happywear obtained?

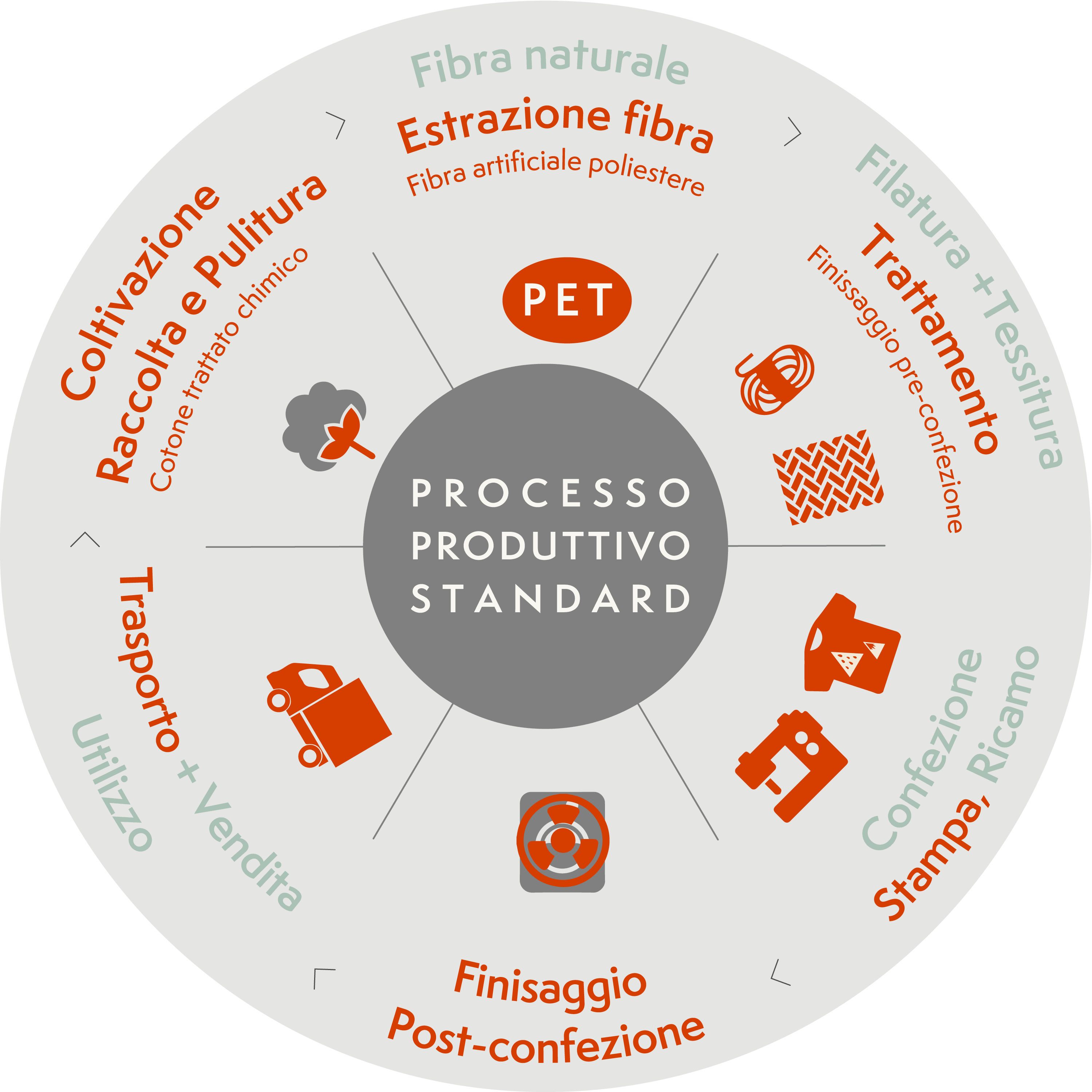

For raw materials such as cotton (natural-vegetal fibre), the fibre is already present in nature and therefore does not need to be extracted. In the case of alternative raw materials such as bamboo or eucalyptus (man-made-natural fibres), the fibre must be extracted in a production process. Depending on how this process is carried out, it can be more or less harmful to the environment.

CORA happywear only uses materials that have a minimal impact on the environment. For example, the process of extracting eucalyptus fibre and turning it into yarn for CORA happywear garments is completely environmentally friendly as it is a closed-loop process: the (organic) solvents and water used are almost 100% recovered. The fibre thus obtained is also biodegradable. When it comes to extracting the fibre from bamboo, more water and chemicals are required.

For this reason, CORA happywear, while waiting for the positive results of new and encouraging researches to make this extraction more eco-sustainable, uses to mix the bamboo fibre with 30% of organic cotton during the spinning phase. With CORA happywear you will discover the special softness that trees give you!

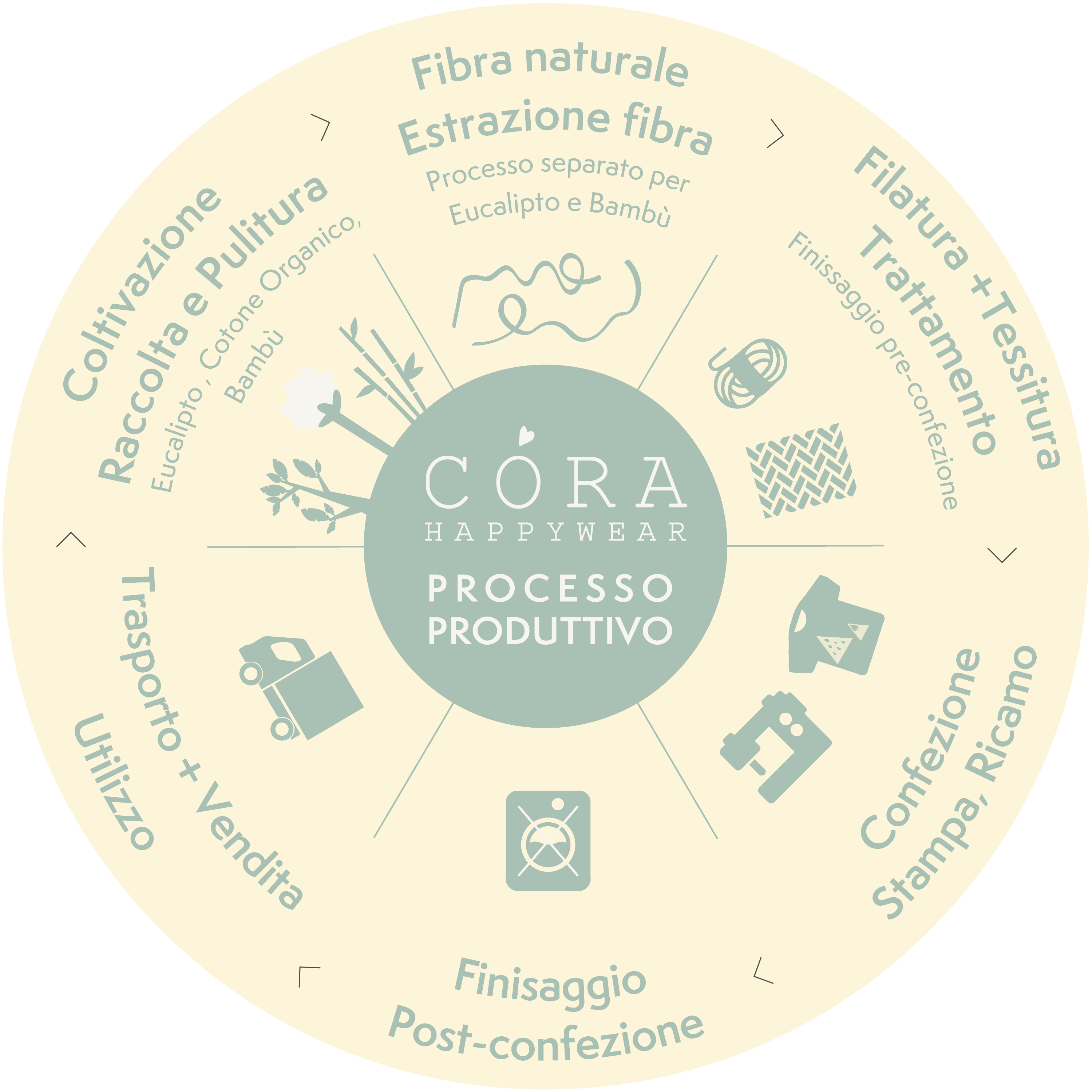

THE STAGES OF PRODUCTION

Raw materials

CORA has been producing sustainably since 2014. Our materials are produced in an environmentally friendly and fair way, thanks to the collaboration with certified suppliers. Sustainable production for CORA is possible through the use of natural fibres. The extraction of cotton, for example, which requires a lot of water and large areas of cultivation, can be done with the rotation of cultures. This means that it does not pollute water because there is no use of pesticides and chemical fertilizers but predator insects and respect of the ground. We use maily new types of raw materials which come from woods - eucalyptus, beeckwood, bambus - which thanks to innovative techniques in the cultivation and production phases are excellent sustainable raw materials for state of the art clothes .

Spinning

Weaving

After the fibre has been harvested naturally or obtained artificially, it is processed into a thread. The thread is then turned into the fabric for the garments. Before the product is ready, it has to go through some processing. For example, the fabrics are washed and dyed or prepared for dyeing. The process of spinning and weaving has no impact on the environment. However, the processing can be harmful if the washes and dyes used require a large amount of chemical agents. CORA happywear therefore only uses washes and dyes that have a very low negative impact on the environment and are not harmful. The dyeing companies CORA works with are GOTS (Global Organic Textile Standard) certified.

Production of eco-sustainable clothing

Cutting and sewing is the start to get to the perfect dress. This phase of production has different manual steps. It has minor impacts on nature. This is for sure the most delicate part from the point of view of the workers in the process. We try to produce our garments in European countries in order to have our supply chain under control. Our Turkish production has the Fair Wear Foundation (FWF) certificate that cares about the workers in the process.

Print and embroidery

In this phase, a print or an embroidery is added to the finished garment. While embroidering does not have meaningful negative consequences, printing can affect the environment negatively if the colours used contain large amounts of chemical agents. Therefore, CORA Happywear only uses water-based colours for its prints, applied through a screen printing technique.

The chemical solvents, usually used to give consistency, plasticity and adherence to the print, are substituted with water. The result is a natural print which is soft to the touch and is highly resistant to repeated lavation.

Finishing of clothes

The last step includes dying, decolouring or obtaining special effects such as a vintage effect on a t-shirt. Considering the entire production process, the finishing process definitely is the most harmful to the environment as the desired results require a significant amount of chemical agents. CORA Happywear has therefore decided to completely avoid this phase.

The final transport to your home

Of course, the transport of the finished garments also has a negative impact on the environment. CORA produces exclusively in the Mediterranean region - Italy, Greece, Turkey - and thus avoids long distances (e.g. Asia). We keep the kilometres that the garment has to travel as low as possible. Please when ordering online and doubting on sizes or fittings call us or write us an email maybe we can avoid unnecessary shipments.